In 2013, Elon Musk talked about the Hyperloop. A futuristic transport system built around near-vacuum tubes designed to whisk passengers between cities at speeds of up to 1,000 km/h (621 mph).

Though Musk has succeeded in electric cars and reusable rockets, Hyperloop languished under immense engineering and financial obstacles, spanning airtight seals, massive temperature shifts, and the complexities of integrating high-speed maglev into everyday infrastructure. A remarkable test project in China shows that Hyperloop-like travel may have a future.

China rescues Elon Musk’s hyperloop dream from oblivion

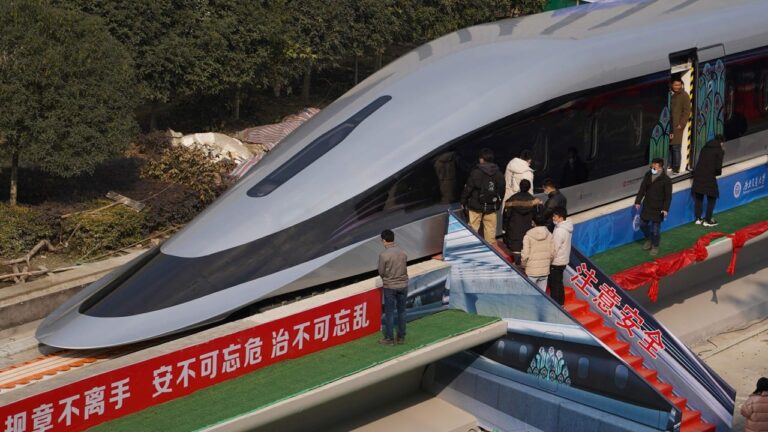

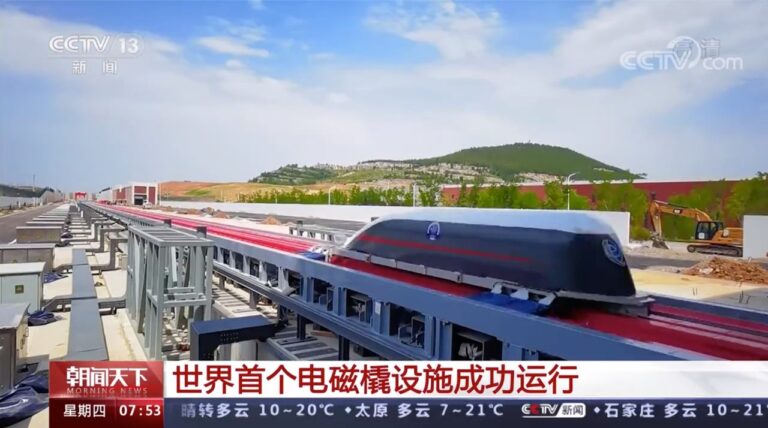

In 2024, Chinese engineers constructed a 2 km (1.2-mile) test line in Yanggao County, Shanxi province, to explore near-vacuum maglev technology. According to a paper by the China Railway Engineering Consulting Group (CREC), a team led by master engineer Xu Shengqiao developed a steel-concrete tube design sealed with epoxy-coated rebar and corrugated steel expansion joints.

This novel combination merges steel’s tensile strength and concrete’s compressive durability, ensuring the tubes remain airtight under harsh conditions ranging from sub-zero winters to 45 °C (113 °F) summers.

Musk’s Hyperloop concept depended on large steel tubes, which are prone to leaks and extreme drag at higher speeds. In contrast, CREC devised methods to cut energy loss by over a third.

Key to their solution was using low-carbon steel grids that reduced the eddy currents plaguing existing maglev designs, particularly when speeds surpassed 1,000 km/h. The result: a vacuum-sealed corridor structurally robust enough to support near-supersonic travel without the crippling heat and pressure complications Musk’s teams encountered.

Overcoming crippling engineering challenges

Building such a system demanded a reinvention of core materials. Traditional steel reinforcements in concrete can warp or crack in near-vacuum conditions—just as standard concrete might crumble when internal air pressure approaches zero.

The Chinese team turned to basalt-fibre concretes, glass-fibre reinforcements, and pre-vacuum curing to counter this. On July 22, 2024, Xu’s group successfully tested a levitating vehicle cruising on a maglev track in a partial vacuum.

They employed laser-guided sensors and AI-driven magnetic dampers to maintain stability while distributed vacuum pumps balanced the pressure. Meanwhile, safety solutions like emergency airlocks and pressure-resistant passenger cabins tackled the same grave concerns that hindered Hyperloop in its early experiments.

The path ahead

According to CREC, the system now has a 2 km test bed and a blueprint for expanding far beyond that. Prefabricated tube segments—offering up to 60% lower costs than traditional all-steel piping—allow for easier scalability.

However, going commercial would require enormous investment, possibly in hundreds of billions of yuan. Issues like thermal expansion over long distances and swift, reliable emergency response design remain under examination.

China is leveraging lessons from its extensive high-speed rail program, where automated welding, laser-guided surveying, and millimeter-level tolerances have already set global records. These engineering habits, advanced superconducting materials, and vacuum technologies may give China an edge in mastering near-vacuum travel at unprecedented speeds.

For Musk, the Hyperloop’s failure highlighted the immense complexity and cost of vacuum tube travel. China’s achievement stands as a second chapter in that saga. Whether this test line evolves into a major commercial venture remains uncertain.

Still, one thing is clear: China has reignited Musk’s abandoned dream with a determination and methodology that could turn near-supersonic ground travel into a viable reality.